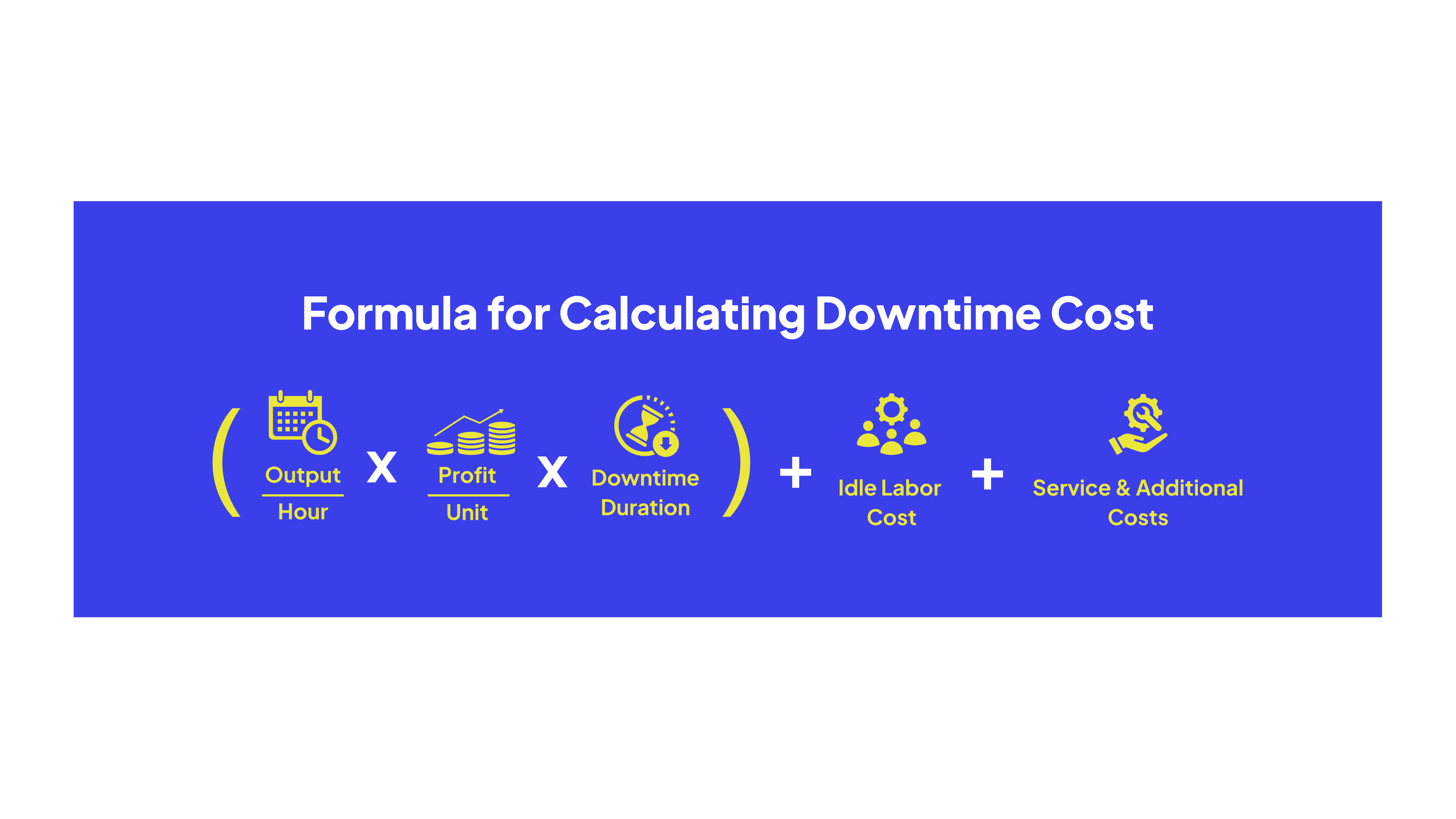

Calculating the True Cost of Downtime in Your Factory

Unplanned downtime acts as a hidden tax on both profitability and customer trust. To quantify the cost of unplanned downtime in manufacturing, start at the line-level: understand the average cost of downtime per critical asset—not just the plant average.

This baseline clarifies where machine downtime reduction will deliver the biggest gains. Beyond direct costs, consider ripple effects: missed SLAs, contractual penalties, overtime, quality rework, and reputational damage.

Preventive vs Predictive: What’s the Difference?

Talk to commsult’s AI experts to start your Predictive Maintenance journey.

Teams often ask the difference between preventive and predictive maintenance.

- Preventive maintenance (PM): Time- or usage-based tasks (e.g., replace every 500 hours). Simple, but can under- or over-maintain.

- Predictive maintenance (PdM): Uses live signals (vibration, temperature, current, acoustics, PLC logs) to predict failure windows and schedule just-in-time interventions.

These strategies mark the evolution from reactive vs preventive maintenance toward condition based maintenance (CBM) supported by continuous condition based monitoring.

Beyond Financial Loss: Compliance and Reputation

In Indonesia, equipment failure isn’t just an operational hiccup; it can escalate to a BPOM issue. CPPOB and PMR demand auditable process control—temperature regulation, dosing/mixing accuracy, and sanitation cycles. AI in food manufacturing with PdM detects process drifts early, reducing recall risk and protecting Halal status and brand trust.

Indonesian recall context (illustrative):

- The “Latiao” contamination demonstrated how temperature-control lapses can cascade into category-wide action.

- The “Roti Okko” process failure showed how deviations and faulty processes jeopardize compliance and certification.

These are the kinds of risks PdM is designed to mitigate.

From Reactive to AI-Powered Maintenance

Manufacturers moving from run-to-failure or basic PM to PdM typically report:

- Meaningful machine downtime reduction (pilot benchmarks ~20%)

- Higher OEE and asset utilization

- Lower spare-parts consumption and overtime

- Fewer compliance incidents

Case Snapshot from PT Mayora Indah Tbk

- Phased, strategic journey (since 2018): Start with data monitoring; scale capabilities gradually.

- Cost-effective implementation: Retrofit existing analog equipment with simple converters instead of full replacements.

- Tangible efficiency gains: Connecting 14 coding machines to a single computer slashed

Discover what commsult’s AI team can improve in your production line.

What You Actually Need (Software & Architecture)

For tangible outcomes, pair analytics with execution:

- Data layer: PLC/SCADA, sensors (vibration, temperature, current), historian.

- Analytics layer: anomaly detection, predictive maintenance IoT models, retraining loop.

- Execution layer: manufacturing maintenance software—a manufacturing CMMS / CMMS for manufacturing—to drive work orders, spares, calendars, and escalation; plus factory maintenance software or manufacturing equipment maintenance software for shop-floor control.

- Integration: SAP/ERP, MES, LIMS for closed-loop actions. Many teams group these as Maintenance Operation software and condition based monitoring solutions or predictive maintenance software for manufacturing.

How It Works

- Crawl (Fase Pilot)

Select a high-impact line; instrument key assets; start condition based monitoring and loss accounting using the downtime formula. Target 1–2 failure modes; set a clear baseline. - Walk (Develop & validate)

Train PdM models with your maintenance engineers’ know-how; integrate alerts into CMMS; track reducing downtime in manufacturing vs the baseline. - Run (Scale & integrate)

Expand to adjacent lines and plants; unify alerts, spares, and scheduling; link PdM to quality checks for BPOM/CPPOB audit trails; publish ROI dashboards for finance and operations.

Conclusion

In Indonesia’s high-pressure F&B market, AI-PdM is not just a technological upgrade—it’s a strategic necessity. It helps cut risks, boost productivity, and accelerate Industry 4.0 food manufacturing adoption while ensuring compliance with BPOM and global food safety standards.

At commsult, we are AI specialists and a trusted technology partner helping manufacturers transition from reactive to predictive operations. Our team combines industrial process expertise, SAP integration experience, and AI-driven maintenance solutions to deliver measurable uptime improvements and compliance assurance

Boost uptime with AI-PdM. Contact Commsult’s AI specialists today.