What Makes a Manufacturing ERP Unique?

ERP for manufacturing companies goes far beyond accounting. It must support operational complexity, including:

- Production Scheduling

Managing multi-step routing across manual and automated lines, with dynamic adjustments when disruptions occur. - Inventory Granularity

Handling complex BOM structures, batch tracking, expirations, and serial numbers. - Warehouse Operations

Integrating seamlessly with a warehouse management system so physical stock movements immediately reflect financial reality.

Generic software treats a product as a simple line item. Specialized software for manufacturing companies must treat a product as a dynamic assembly of parts, labor, and machine time. Off-the-shelf ERP systems struggle to handle variability on the factory floor without manual workarounds that compromise data integrity.

Cloud-Based ERP and SaaS Manufacturing Software

Modern manufacturing demands flexibility. Legacy, on-premise systems are heavy capital expenditures (CAPEX) that are hard to update. Cloud manufacturing software and SaaS manufacturing software offer distinct advantages for the modern decision-maker:

- Financial Flexibility

Predictable operating expenses instead of heavy upfront investment. - Security and Updates

Continuous improvements without disruptive upgrade cycles. - Remote Visibility

Real-time access to production and warehouse data across multiple sites. - Integration

API-based connectivity with MES, IoT devices, and analytics platforms.

See how a custom MES turns fragmented manufacturing operations into a single real-time execution flow in our MES guide on transforming manufacturing and warehouse operations.

Integrating ERP with Warehouse Management Systems (WMS)

The most powerful ERP is one that speaks directly to the warehouse. By integrating manufacturing resource planning software with WMS logic, you can achieve:

- Real-Time Inventory Tracking

Stock levels update instantly as materials move. - Order Accuracy

Production orders are released only when materials are physically available. - Automation

Procurement and replenishment are triggered by actual stock levels.

Unlike generic ERPs that rely on loose API connections or third-party middleware to talk to a WMS, commsult builds the WMS logic directly into the ERP workflow. This provides a single source of truth for both finance and logistics.

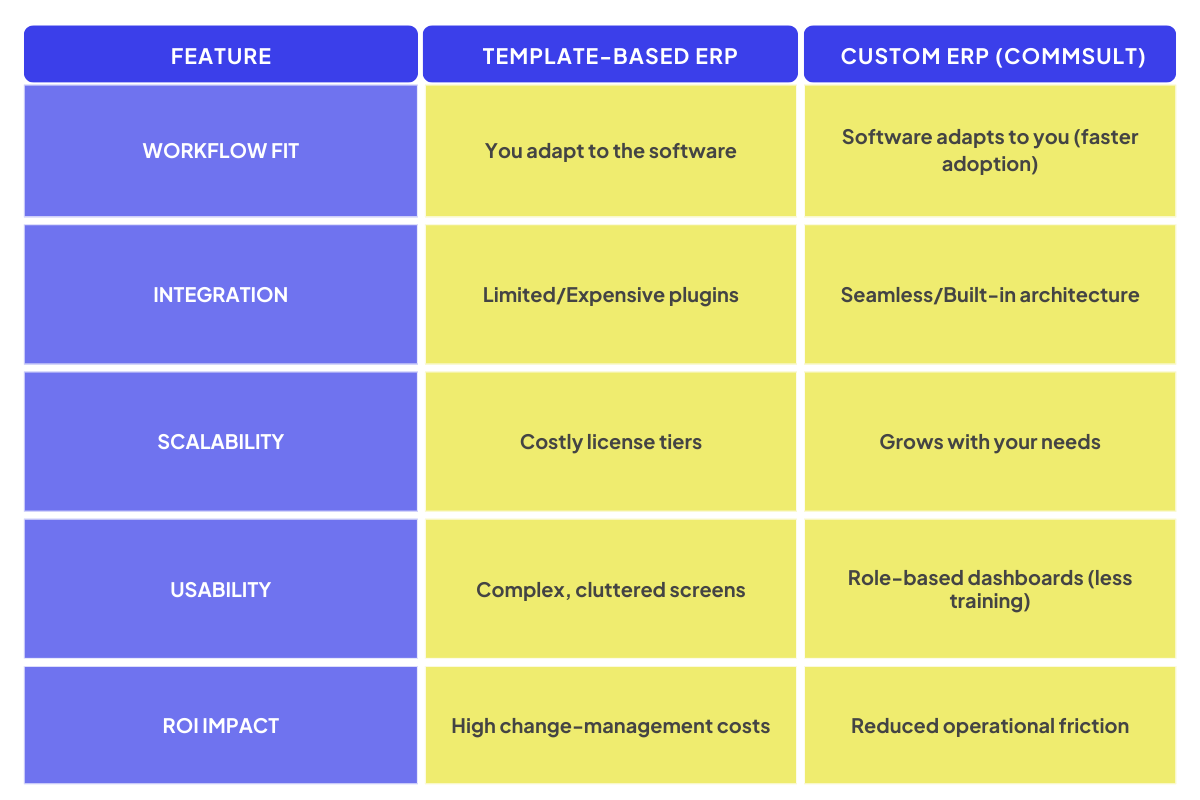

Template-Based vs Custom ERP

Evaluating the best ERP systems for manufacturing requires looking beyond features to outcomes.

Stop Adapting to Software. Build ERP around Your Operations!

Key Modules We Build for Custom ERP

We don't just install; we architect a custom system. Our key modules include:

- Inventory and Warehouse

Custom logic for specific storage types to reduce stock variance and eliminate "ghost inventory." - Production and MRP

Scheduling algorithms that match your machine capacity to maximize throughput. - Quality and Maintenance

Integrated directly into the production flow to increase machine uptime. - Analytics

Dashboards that show specific bottlenecks, helping you improve Overall Equipment Effectiveness (OEE).

Case Insight: ERP and WMS in Indonesia

PT Kalbe Farma Tbk operates a highly regulated, temperature-sensitive supply chain across 76 branches and more than 200,000 outlets.

By implementing an integrated digital ecosystem that connects their ERP with a specialized WMS and the Mostrans logistics platform, they bridged the critical gap between financial planning and physical logistics. This architecture reduced obsolescence risk while maintaining strict batch and expiration control.

Build ERP That Fits Your Factory

We build custom ERP systems that align with your production and warehouse workflows. Talk to our experts and prepare your operation for the next stage of digital manufacturing.

Ready to take the next step? Learn how ERP connects to the Smart Factory.