What Is an MES System in Manufacturing?

To understand the solution, it is important to answer a common question: what is an MES system in manufacturing?

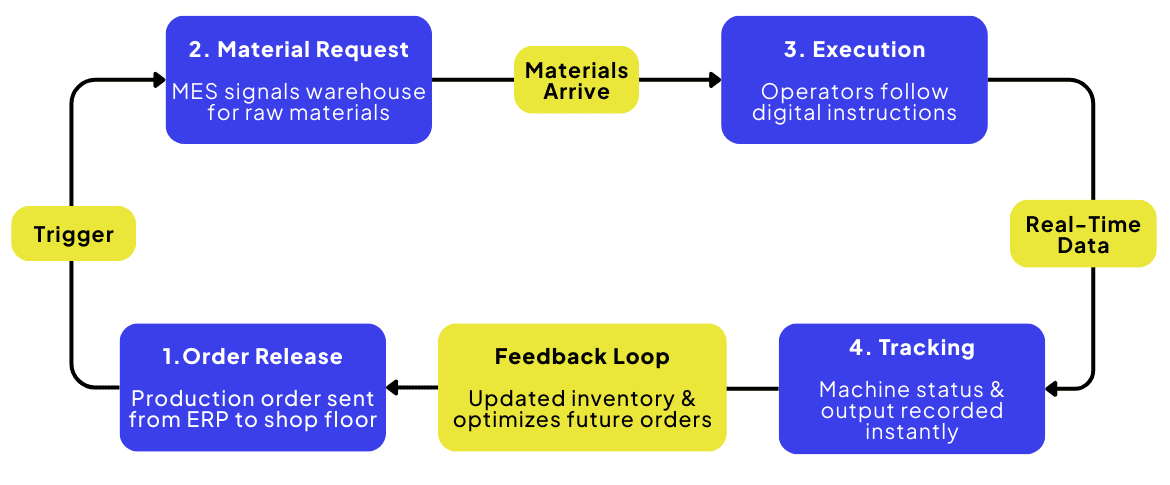

A MES manufacturing execution system is the digital brain of the factory floor. While business decisions and planning happen in the office, MES operates where production actually occurs.

It tracks, controls, and documents the transformation of raw materials into finished goods in real time. A well-designed MES connects machines, operators, and warehouse movements into a single digital execution flow.

The Difference Between MES and ERP

Many manufacturers are still unclear about the difference between MES and ERP. They are distinct layers of the same manufacturing technology stack:

- ERP ( Enterprise Resource Planning) focuses on planning. It manages finance, procurement, sales orders, and long-term production plans.

- MES (Manufacturing Execution System) focuses on execution. It manages machine uptime, quality checks, work orders, and shop-floor scheduling in seconds, not weeks.

To run a modern factory, you cannot rely on manufacturing execution system modules inside ERP platforms that are little more than generic add-ons. Many manufacturers fall into the trap of using these so-called free modules because they appear convenient.

The reality is that ERPs are architected for finance and long-cycle planning, with updates measured in days or weeks. Production, however, operates in seconds. Using an ERP for execution creates a dangerous time lag, a data blind spot where the office has no visibility into a machine failure or a ruined batch until the shift is already over.

What manufacturers need instead is specialized manufacturing execution system software that acts as a true bridge between the top floor planning and the shop floor action. A custom MES closes this gap by translating high-level ERP planning and financial objectives into precise, step-by-step digital instructions for operators on the factory floor.

For a deeper explanation of ERP planning layers, see our guide on building a custom ERP system for manufacturing.

Build A Custom MES That Fits How Your Factory Actually Works!

Real-Time Warehouse and Inventory Control

A custom MES does more than monitor machines. It also functions as manufacturing process management software that connects production directly to warehouse operations.

- Raw Material Tracking

When a machine consumes material, inventory is deducted instantly. No more end-of-shift counting errors. - Finished Goods Visibility

As soon as a product is packed, the MES updates the warehouse system, making it available for shipping immediately.

This is where commsult’s custom approach makes a difference. We don't just connect data points. We visualize them through custom warehouse visibility dashboards. Unlike generic factory production management software that forces you to use standard reports, we build dashboards that map directly to your unique material flow.

Why Off-the-Shelf MES Software Fails

Every factory has its own constraints, layouts, and processes. Off-the-shelf factory production management software forces manufacturers to adapt their workflows to rigid templates.

The result is wasted features, missing capabilities, and low user adoption. Generic MES platforms struggle to handle mixed manual and automated lines, legacy equipment, or industry-specific traceability requirements.

The Benefits of a Custom MES Solution

At commsult, we believe software should adapt to you. A custom MES solution is built to handle the complexities that generic software ignores.

- Seamless ERP Integration

We design MES integrations that respect your existing data structure, including complex multi-level Bill of Materials (BOM) or specific routing requirements - Custom Dashboards

Get visibility that matters to your process. Plant managers, supervisors, and warehouse teams see exactly the data they need, from multi-level quality control to batch traceability. - IoT and PLC Integration

Real factories are rarely uniform. Whether you operate mixed manual assembly and automated production lines, or legacy PLCs alongside modern sensors, we connect them into a single source of truth.

This approach positions MES as the execution foundation that supports ERP planning and enables future smart factory and Industry 4.0 initiatives.

Ready To Turn Manufacturing Complexity Into An Advantage?

Case Insight: Custom MES for an Indonesian Manufacturer

PT Mattel Indonesia, recognized by the Ministry of Industry as a National Lighthouse for Industry 4.0, illustrates the impact of a tailored MES approach.

To support the production of more than 100 million dolls annually, the factory needed to synchronize automated molding with labor-intensive manual assembly. Generic software could not handle this complexity.

By implementing a custom MES architecture, diverse machinery and manual workstations were integrated into a single real-time execution network. This ensured smooth material flow across the factory and supported a facility that contributes over 35% of Indonesia’s toy exports.

Ready to Take Control of Your Production?

Stop settling for disconnected systems. Modern manufacturing demands more than generic software. It requires execution systems that reflect how your factory truly operates. With commsult, you can regain real-time visibility, control, and scalability where it matters most.

Take Control of Your Production, Build Your Mes with commsult!